The Warehouse of Tomorrow: How AI and Robotics Are Revolutionizing Logistics

Robots are no longer just a sci-fi fantasy; they're already a key part of modern warehouses. But their role is set to become even more sophisticated, with artificial intelligence (AI) acting as the brain behind the brawn. This powerful combination is creating a new era of logistics that is faster, more efficient, and more responsive than ever before

Autonomous mobile robots navigating a logistics warehouse

Real-World Examples of Future Logistics Automation

This vision of the future is already being built by leading companies around the globe.

-

Amazon: Amazon is a pioneer, expanding its robot fleets beyond simple picking to handle more complex tasks like packing and sorting, significantly increasing its operational speed.

-

JD.com (China): The Chinese e-commerce giant has created highly automated warehouses that operate with minimal human intervention, showcasing the potential for near-total automation.

-

DHL: The global logistics leader is using AI-powered vision systems to quickly identify packages and optimize how they are loaded, improving efficiency and accuracy.

-

Cainiao (Alibaba): Cainiao, the logistics arm of Alibaba, has developed "smart logistics parks" in China where thousands of Autonomous Mobile Robots (AMRs) work simultaneously, demonstrating the power of scale in automation.

Robotics in the Future Warehouse

The robots we see today are just the beginning. In the coming years, we can expect to see them become more versatile and intelligent.

-

Autonomous Mobile Robots (AMRs): Currently used for simple tasks like transporting goods and picking items, future AMRs will be true multi-taskers. They'll be able to pick, sort, and pack items, all while navigating complex warehouse environments on their own.

-

Robotic Arms and Grippers: Modern robotic arms are already quite adept at handling fragile and unusually shaped items. In the future, thanks to AI, they will be able to adapt to millions of unique items (SKUs) on the fly without needing to be pre-programmed for each one. This will make them incredibly flexible.

-

Automated Guided Vehicles (AGVs) vs. AMRs: Today's AGVs follow fixed, pre-defined paths. AMRs, on the other hand, can adapt to their surroundings dynamically. As technology improves, we'll see a clear shift toward AMRs, which offer greater autonomy, safety, and flexibility.

-

Collaborative Robots (Cobots): Currently, cobots work alongside humans on tasks like packing and quality inspection. In the future, they'll become even more seamless partners, using natural language to communicate and support their human coworkers.

cobots work alongside humans on tasks

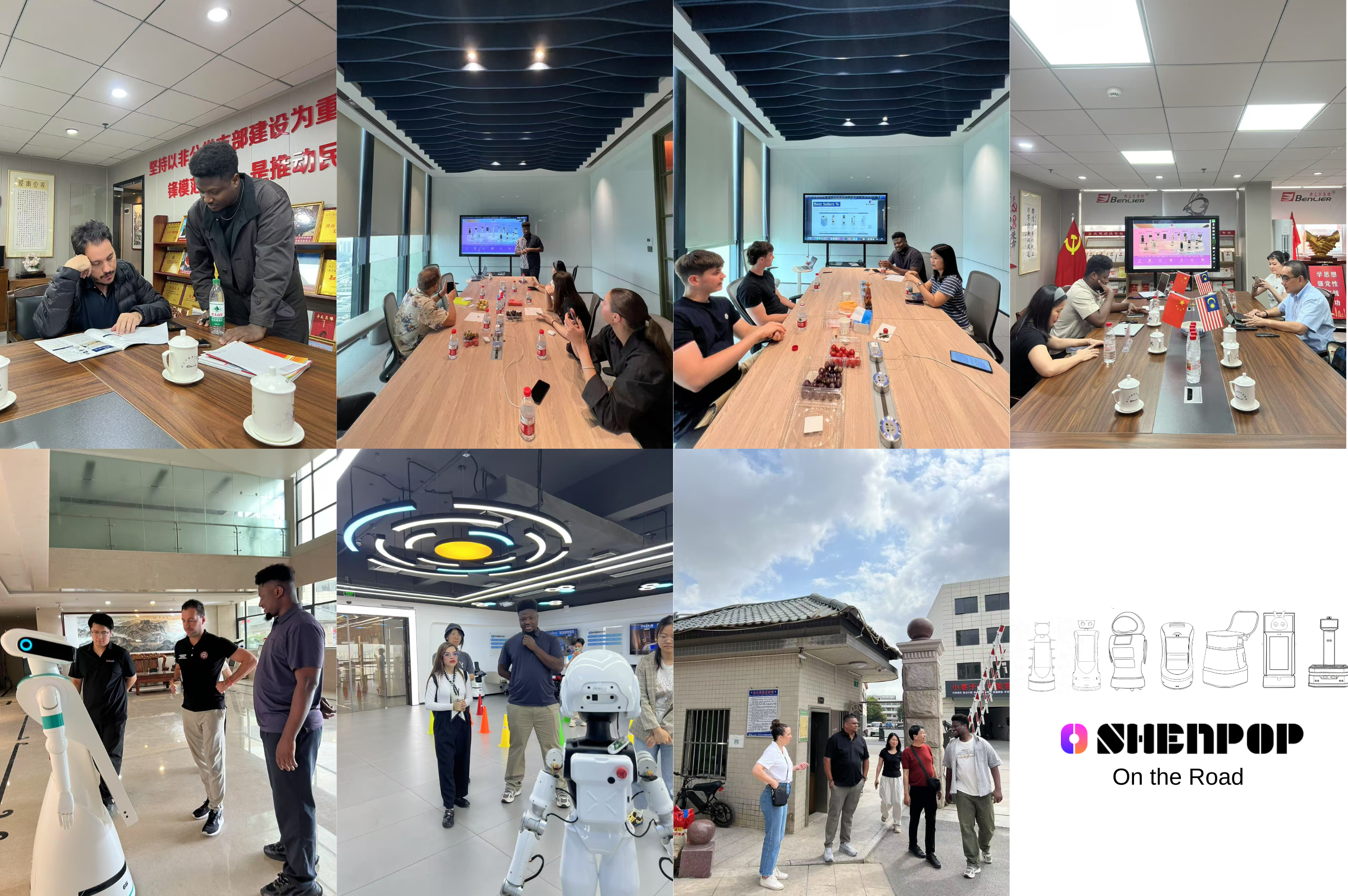

Want to prepare your workforce for the future of logistics automation? Contact Shenpop Robotics for training and deployment support.

AI: The Brain of Logistics Automation

Robots might be the muscle, but AI is the brain. It's the engine that powers the next generation of warehouse automation.

-

Predictive Demand Forecasting: Using AI, warehouses can predict future order volumes with incredible accuracy. This allows them to proactively manage staffing and efficiently allocate robots to where they'll be needed most.

-

Dynamic Route Optimization: AI gives robots and delivery fleets the ability to adjust their routes in real time. They can factor in traffic, changing demand, and even weather to ensure the fastest possible movement of goods.

-

Inventory Visibility: Forget manual inventory checks. Future warehouses will use AI-powered drones and computer vision to perform automated cycle counts, giving them a real-time, highly accurate view of what's in stock.

-

Autonomous Decision-Making: AI will be able to determine which robot is best suited for a specific task and assign it for maximum efficiency. This ensures that every task is performed by the best tool for the job.

-

Predictive Maintenance: AI will analyze robot performance data to predict when maintenance is needed, allowing for repairs to be scheduled before a breakdown occurs. This will minimize downtime and keep operations running smoothly.

The synergy between advanced robotics and intelligent AI is not just a trend; it’s a complete transformation of the supply chain. The warehouse of tomorrow will be a hyper-efficient, highly responsive ecosystem where humans and robots work together to meet the demands of a fast-paced world.

Want to prepare your workforce for the future of logistics automation? Contact Shenpop Robotics for training and deployment support.